7 Common Applications of Phase Change Materials (PCMs) in Modern Industry

In an era driven by sustainability, energy efficiency, and smart technology, the use of Phase Change Material PCM is soaring across various sectors. These fascinating substances, capable of absorbing or releasing large amounts of heat during phase transitions, are redefining thermal management in the modern world.

Whether it’s to regulate temperature, enhance energy storage, or improve comfort, the versatility of phase change technology is second to none. In this guest post, we’ll explore 7 common applications of Phase Change Materials (PCMs) across industries, highlighting real-world examples and insights from industry leader DATUM PHASE CHANGE LTD.

What is Phase Change Material PCM?

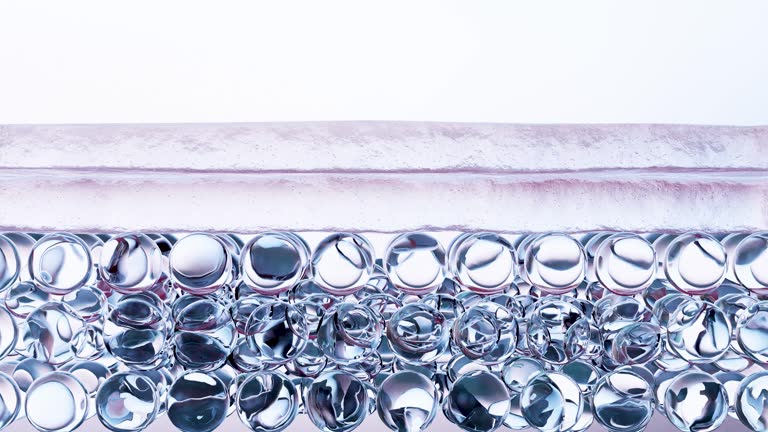

A Phase Change Material PCM is a substance that absorbs and releases thermal energy during the process of melting and solidifying at a specific temperature. This unique property allows it to maintain a consistent temperature by storing or releasing latent heat.

Unlike conventional insulation, which slows heat transfer, PCMs regulate temperature dynamically, making them ideal for a variety of industries. Think of it as a smart thermal battery that charges and discharges heat.

Application 1: Building & Construction

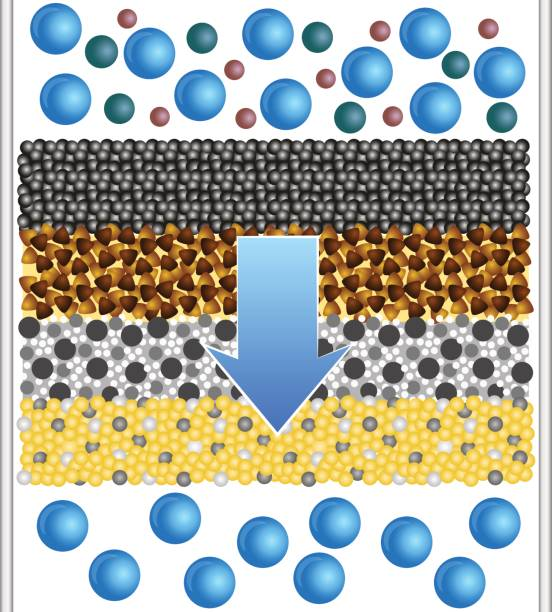

The construction industry has witnessed a major transformation through the integration of phase change material for cooling and thermal storage.

PCMs are used in walls, ceilings, and floors to:

- Stabilise indoor temperatures

- Reduce reliance on HVAC systems

- Lower energy consumption during peak hours

DATUM PHASE CHANGE LTD offers cutting-edge PCM solutions for residential, commercial, and institutional buildings. Their products are seamlessly integrated into gypsum boards, insulation panels, and ceiling tiles—making thermal comfort both efficient and invisible.

Moreover, PCMs enhance building energy ratings, helping projects meet sustainability certifications like BREEAM and LEED.

Application 2: Cold Chain & Food Transportation

Maintaining the cold chain is critical in the transport of food, pharmaceuticals, and sensitive perishables. PCMs are pivotal in refrigerated logistics, providing passive temperature control without active refrigeration.

Use cases include:

- Insulated containers and packaging

- Refrigerated trucks and cargo units

- Vending machines and food delivery boxes

With Phase Change Material PCM technology, consistent temperatures can be maintained for hours—even days—without external power. This ensures product quality and regulatory compliance across borders.

DATUM PHASE CHANGE LTD tailors PCM formulations to meet temperature requirements between -40°C and +30°C, addressing the full cold chain spectrum.

Application 3: Data Centres & Electronics

As data centres become the digital heart of modern economies, cooling systems face growing pressure. PCMs offer a passive method to manage heat surges, reducing reliance on energy-intensive air conditioning.

Benefits include:

- Emergency heat storage during power failures

- Peak load shaving

- Thermal regulation of sensitive server zones

PCMs can also be applied in consumer electronics, preventing overheating in devices like smartphones, laptops, and wearable tech.

By integrating phase change technology, companies can reduce downtime, extend equipment lifespan, and meet stricter environmental targets.

Application 4: Renewable Energy Storage

One of the biggest challenges with renewable energy sources like solar and wind is intermittent supply. PCMs are instrumental in storing excess energy in the form of heat, which can be released when needed.

Common applications:

- Solar thermal collectors

- Off-grid heating systems

- Thermal batteries for solar cookers

By combining PCMs with photovoltaic panels or solar water heaters, DATUM PHASE CHANGE LTD delivers hybrid systems that balance supply and demand, especially in off-grid or rural regions.

This makes PCMs a linchpin in the transition to cleaner, more decentralised energy systems.

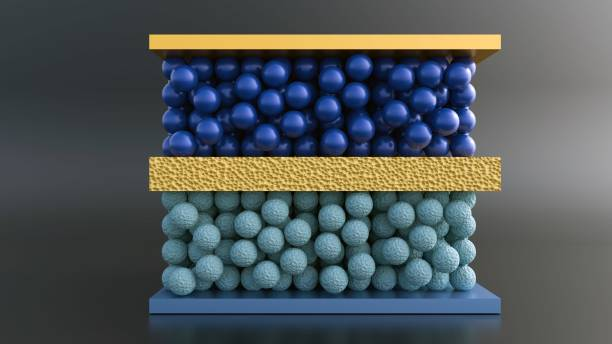

Application 5: Automotive & Electric Vehicles (EVs)

The automotive industry is embracing PCMs for enhanced safety, comfort, and energy management.

Key applications include:

- Battery thermal management in EVs

- Cabin temperature control

- Thermal shielding of components

In EVs, temperature-sensitive lithium-ion batteries can degrade or fail under heat stress. PCM wraps or packs regulate their operating temperature, boosting performance and lifespan.

With a strong R&D background, DATUM PHASE CHANGE LTD offers automotive-grade PCMs that meet rigorous industry standards, from high impact resistance to thermal conductivity.

Application 6: Medical & Pharmaceutical

Precision temperature control is vital in healthcare—whether in surgery rooms, patient care, or pharmaceutical storage.

PCMs are used for:

- Vaccine transportation

- Thermoregulated blankets and dressings

- Organ transport containers

- Body cooling systems during surgery

Unlike traditional gel packs, PCMs provide consistent temperature maintenance within ±1°C, making them ideal for critical medical use.

DATUM PHASE CHANGE LTD has collaborated with healthcare providers and pharmaceutical companies to design tailor-made solutions that prioritise patient safety and product efficacy.

Application 7: Textile & Personal Comfort

Last but not least, PCMs are making their way into our everyday lives—literally. Clothing, bedding, and accessories now integrate PCMs to improve thermal comfort.

Examples include:

- Thermoregulating sportswear and uniforms

- Heated or cooling mattresses and pillows

- Outdoor gear for extreme climates

These products absorb body heat when temperatures rise and release it when temperatures fall—creating a personal microclimate.

DATUM PHASE CHANGE LTD’s proprietary phase change material for cooling textiles has found its way into military kits, astronaut gear, and consumer fashion.

The Future of Phase Change Technology

The versatility of PCMs ensures their continued expansion across even more sectors—urban farming, aerospace, aviation, and even 3D printing.

With ongoing research into bio-based PCMs and encapsulation techniques, the next generation of phase change materials promises even greater performance, safety, and sustainability.

DATUM PHASE CHANGE LTD continues to lead this charge, investing in material science, real-world testing, and sustainable sourcing.

Conclusion

The range of applications for Phase Change Material PCM continues to grow as industries pursue smarter, cleaner, and more efficient solutions. From buildings to batteries, textiles to transport, PCMs are proving to be one of the most versatile and sustainable thermal technologies available today.

With deep expertise and innovative products, DATUM PHASE CHANGE LTD remains at the forefront of this evolution, helping industries around the globe transition to more resilient and efficient thermal systems.

FAQs

What temperature ranges can Phase Change Material PCM cover?

PCMs are available in a wide range of melting points—from as low as -50°C to over 100°C—depending on the application.

Is Phase Change Material PCM safe to use?

Yes, high-quality PCMs used by DATUM PHASE CHANGE LTD are non-toxic, non-flammable, and meet international safety standards.

Can PCM be reused multiple times?

Absolutely. PCMs can undergo thousands of phase cycles without degradation, making them cost-effective over the long term.

How is PCM different from traditional insulation?

Traditional insulation slows heat flow, while PCMs store and release heat, actively stabilising temperatures.

Can PCMs be used in small devices like phones or watches?

Yes. Microencapsulated PCMs can be embedded in electronics to manage internal heat and improve user comfort.

Do PCMs work in both hot and cold environments?

Yes, they are effective in absorbing excess heat in warm conditions and releasing it in cooler environments, offering year-round performance.