Carbon Wrapping Solutions for Slabs: Essential Services for Structural Safety

Table of Contents

In India’s rapidly evolving construction landscape, ensuring the structural integrity of buildings is paramount. With increasing urbanization and the challenges posed by ageing infrastructure, innovative solutions are required to maintain and enhance the safety of structures. One such advancement is carbon wrapping for slabs, a technique that offers a robust method for reinforcing and extending the lifespan of concrete slabs.

Understanding Carbon Wrapping for Slabs

Carbon wrapping for slabs refers to the application of carbon fiber-reinforced polymer (CFRP) sheets or fabrics to the surface of concrete slabs. These components are bonded with high-strength epoxy resins, resulting in a composite structure that considerably improves the slab’s load-bearing capability and resilience to environmental conditions. This approach is especially useful for structures that have degraded owing to reasons such as overload, corrosion, or seismic activity.

Benefits of Carbon Wrapping for Slabs

Enhanced Structural Strength

Carbon wrapping for slabs greatly improves the flexural and shear strength of concrete parts. By spreading loads more uniformly, stress concentrations are reduced, lowering the danger of cracks and structural failures. This upgrade is critical for buildings that experience dynamic loads or require greater load capacities due to changes in usage.

Lightweight and Non-Intrusive

Unlike traditional reinforcement methods, which can add significant weight to a building, carbon wrapping is lightweight, ensuring that existing load-bearing parts are not overburdened. Furthermore, the application method is non-intrusive, allowing for reinforcement without major changes to the building’s architecture or prolonged downtime.

Corrosion Resistance

Carbon fiber materials are naturally corrosion resistant, making them appropriate for usage in areas prone to dampness, chemicals, or saltwater conditions. This feature ensures the lifespan of the reinforcement, lowering maintenance costs and increasing the structure’s endurance.

Rapid Installation

Carbon wrapping installation is less time-consuming than traditional procedures. This efficiency reduces disruptions to building operations, which is especially beneficial for commercial or residential properties that cannot afford long periods of inactivity.

Cost-Effective Solution

While carbon wrapping may require a higher initial investment than other methods, the long-term benefits, such as decreased maintenance, increased lifespan, and reduced downtime, lead to overall cost savings. This makes it a financially feasible option for many property owners and developers.

Applications in the Indian Context

Retrofitting Aging Infrastructure

Many structures in India’s urban areas were built decades ago and were not designed to withstand modern load requirements or seismic considerations. Carbon wrapping for slabs is a practical way to retrofit these structures, increasing their safety and compliance with current regulations.

Enhancing Seismic Resilience

Given India’s earthquake proneness, particularly in places such as the Himalayas and Northeast, strengthening building seismic resilience is crucial. Carbon wrapping increases slab ductility and energy absorption capacity, resulting in improved seismic performance.

Industrial and Commercial Buildings

In industrial environments, floors and slabs are frequently subjected to heavy machinery and dynamic loads. Carbon wrapping strengthens these parts, allowing them to bear such loads while maintaining structural integrity. Similarly, commercial structures benefit from enhanced load-bearing capacity, which can accommodate changes in usage or occupancy.

Heritage Structures

India’s rich architectural legacy includes various old buildings that must be preserved. Carbon wrapping offers a minimally invasive way to strengthen slabs in ancient structures, preserving their aesthetic and cultural significance while ensuring safety.

The Process of Carbon Wrapping for Slabs

Assessment and Planning

A detailed structural assessment is performed to determine the level of reinforcement required. This includes assessing the current conditions, determining the load needs, and identifying areas of concern.

Surface Preparation

The slab surface is cleaned and prepared to ensure proper adherence of the carbon fiber elements. This may include cleaning loose particles, fixing cracks, and adding primer.

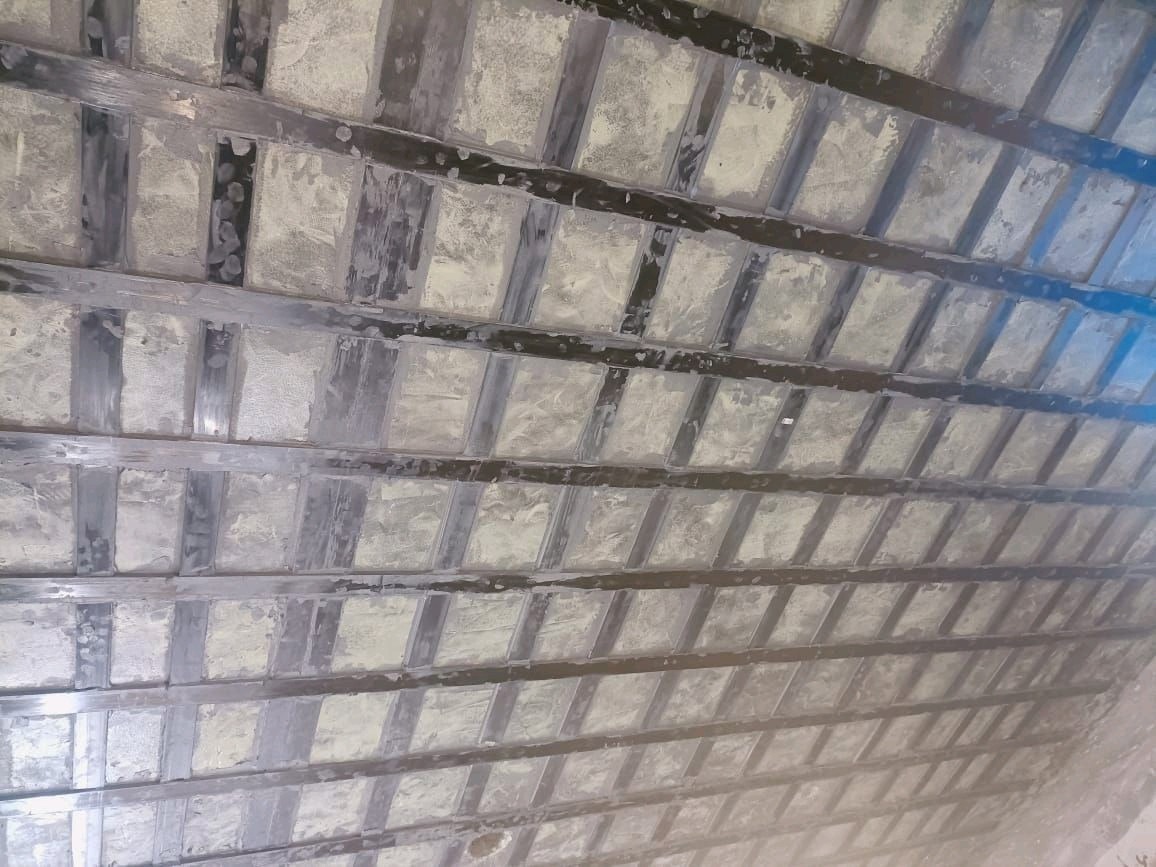

Application of Carbon Fiber Materials

Carbon fiber sheets or textiles are trimmed to the appropriate size and impregnated with epoxy resin. They are then placed to the prepared surface, ensuring accurate alignment and coverage.

Curing

The applied ingredients are allowed to cure, resulting in a solid bond with the concrete slab. This curing period is critical to getting the necessary structural improvement.

Quality Assurance

Inspections are undertaken after installation to ensure that the reinforcement is functional. This could include load testing or non-destructive evaluation procedures to guarantee compliance with safety regulations.

Choosing the Right Service Provider

Selecting a certified and experienced service provider is critical to the effective deployment of carbon wrapping for slabs. Factors to consider are:

- Expertise: The provider should have previous experience with structural reinforcing projects

- Compliance: Ensure adherence to local building codes and international standards.

- Quality Materials: Use of certified carbon fiber products and high-grade epoxy resins.

- Comprehensive Services: Providing complete solutions from assessment to post-installation assistance.

Carbon wrapping for slabs is a game-changing innovation in the field of structural reinforcement. Its implementation in India tackles major concerns such as ageing infrastructure, seismic susceptibility, and the need for efficient, long-lasting, and cost-effective strengthening techniques. By using this technology, property owners, engineers, and developers may ensure the safety, lifespan, and resilience of their structures, leading to a more secure built environment