Five Major Industries That Couldn’t Operate Without Self-Drilling Screws

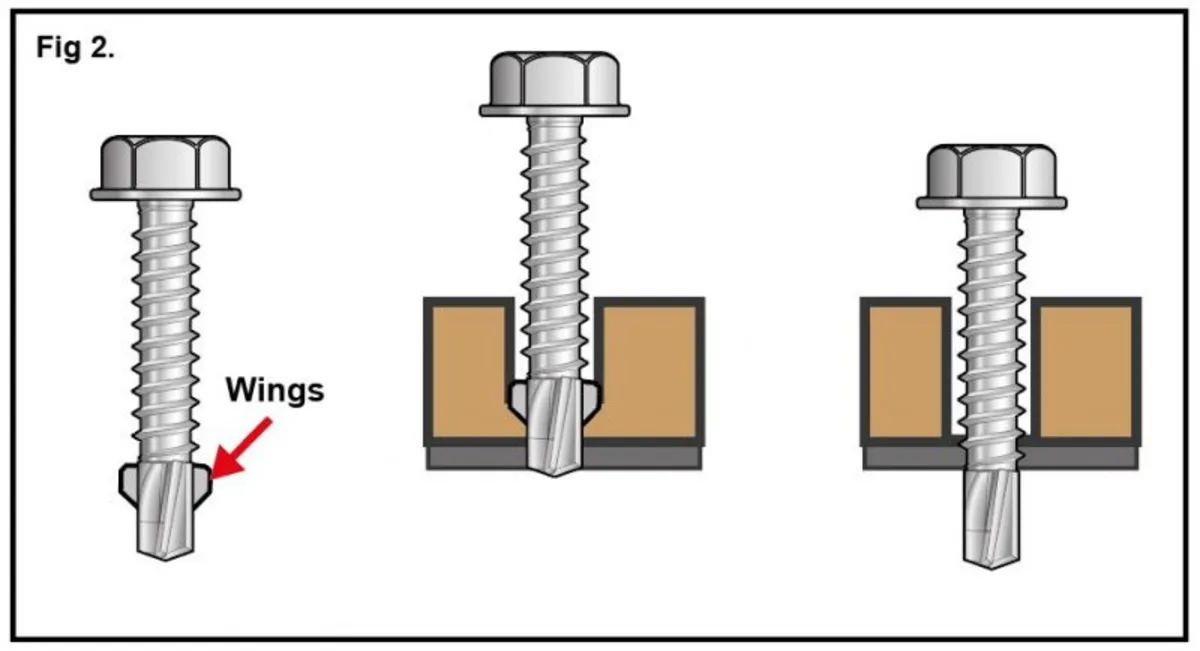

Self-drilling screws have revolutionized fastening technology, offering efficiency, strength, and versatility that traditional screws and fasteners cannot match. Their unique design integrates a drill bit tip with the screw body, enabling users to drill and fasten in one step without pre-drilling holes. This innovation saves time, reduces labor costs, and improves joint integrity, making self-drilling screws indispensable in many industries. In this article, we explore five major industries that rely heavily on self-drilling screws and how these fasteners enhance their operations.

Construction Industry

The construction sector is considered one of the primary users of self-drilling screws. From commercial buildings to residential housing, these fasteners play a critical role in framing, roofing, and metal assembly.

Efficiency in Metal-to-Metal Fastening: Self-drilling screws are widely used for fastening steel studs, metal roofing panels, and other sheet metals. Their ability to penetrate metal without pre-drilling streamlines the assembly process, reducing project timelines.

Durability and Strength: Manufactured with hardened steel and often coated with corrosion-resistant materials, these screws ensure long-lasting connections even in harsh weather conditions. This durability is essential in structural applications where safety and stability are paramount.

Versatility in Materials: In addition to metal, self-drilling screws are capable of securing wood, plastic, and composite materials, offering broad adaptability for different building needs.

Automotive Industry

In the automotive sector, precision and reliability are critical. Self-drilling screws are essential fasteners in vehicle manufacturing and repair, offering secure assembly while minimizing the risk of component damage.

Lightweight Assembly: Modern vehicles utilize lightweight metals like aluminum and thin-gauge steel to improve fuel efficiency. Self-drilling screws can fasten these materials efficiently without compromising structural integrity.

Speed and Consistency: The integrated drilling and fastening reduce assembly time, crucial in high-volume production lines. Consistent torque control also ensures uniform fastening, reducing defects and improving safety.

Aftermarket Repairs: Self-drilling screws are widely used in automotive repairs due to their ease of use and ability to securely attach replacement parts without the need for additional tools.

HVAC Industry

Heating, ventilation, and air conditioning (HVAC) systems rely on a variety of sheet metals, ducts, and components that require secure fastening. Self-drilling screws are the preferred fasteners for their speed and reliability.

Fast Installation of Ductwork: The screws enable technicians to quickly attach duct sections and brackets, even in tight or awkward spaces where pre-drilling is impractical.

Corrosion Resistance: Many HVAC applications expose fasteners to moisture and temperature fluctuations. Self-drilling screws with specialized coatings resist rust, maintaining system integrity and longevity.

Reduced Labor Costs: By eliminating pre-drilling steps, self-drilling screws lower installation time and labor costs, critical factors in competitive HVAC service environments.

Electrical Industry

The electrical industry uses self-drilling screws extensively in panel assembly, conduit installation, and equipment mounting. Their efficiency and reliability make them ideal for securing electrical components.

Secure Panel Mounting: Self-drilling screws fasten electrical panels to metal frames or cabinets quickly and securely, ensuring safe housing of critical components.

Conduit and Cable Management: These screws help attach conduits and cable trays to structural elements with minimal effort, reducing installation time and potential damage to wiring.

Safety and Compliance: The consistent fastening strength supports compliance with electrical safety standards, preventing loosening that could cause electrical hazards.

Aerospace Industry

Though aerospace applications demand the highest standards of safety and precision, self-drilling screws have found their place in non-critical fastening tasks within this sector.

Lightweight and High-Strength Materials: Aerospace components often use aluminum alloys and composites. Self-drilling screws provide a secure fastening method that minimizes damage to these sensitive materials.

Precision Assembly: The aerospace manufacturing process benefits from the precision and repeatability of self-drilling screws, ensuring fast, reliable assembly of support structures and interior fittings.

Maintenance and Repairs: Quick fastening solutions are crucial for aerospace maintenance crews, and self-drilling screws enable faster turnaround times for repairs without compromising safety.

Why Self-Drilling Screws Are Essential Across Industries

The common thread across these industries is the need for fast, reliable, and strong fastening solutions that improve efficiency and reduce costs. Self-drilling screws meet these demands by combining drilling and fastening into a single step, eliminating the need for pre-drilling holes, and reducing tool changes.

Moreover, their design reduces the risk of material damage, such as metal warping or wood splitting, which can occur with traditional fasteners. Coatings and materials tailored to resist corrosion, high temperatures, and mechanical stress extend the lifespan of assemblies in harsh environments.

Practical Advice for Choosing Self-Drilling Screws

Material Compatibility: Select screws made from materials compatible with the substrates to avoid galvanic corrosion, especially when fastening dissimilar metals.

Coating Type: For outdoor or humid environments, opt for corrosion-resistant coatings such as zinc plating or epoxy.

Size and Length: Ensure the screw length is sufficient to penetrate both materials for a secure hold without protruding excessively.

Head Style: Choose appropriate head types (e.g., hex, pan, or flat) based on the application and aesthetic requirements.

Conclusion

baut – tokohasil – Self-drilling screws have become indispensable fasteners across multiple industries, from construction and automotive to HVAC, electrical, and aerospace. Their innovative design offers significant time savings, superior fastening strength, and versatility, enabling industries to meet growing demands for efficiency and quality. For professionals in building and industrial sectors, understanding the benefits and applications of self-drilling screws is essential to optimizing their projects and maintaining high standards of safety and durability.