How to Choose the Right Electrical Conduit Pipe for Your Project

1. Introduction: Why Electrical Conduit Pipes Matter

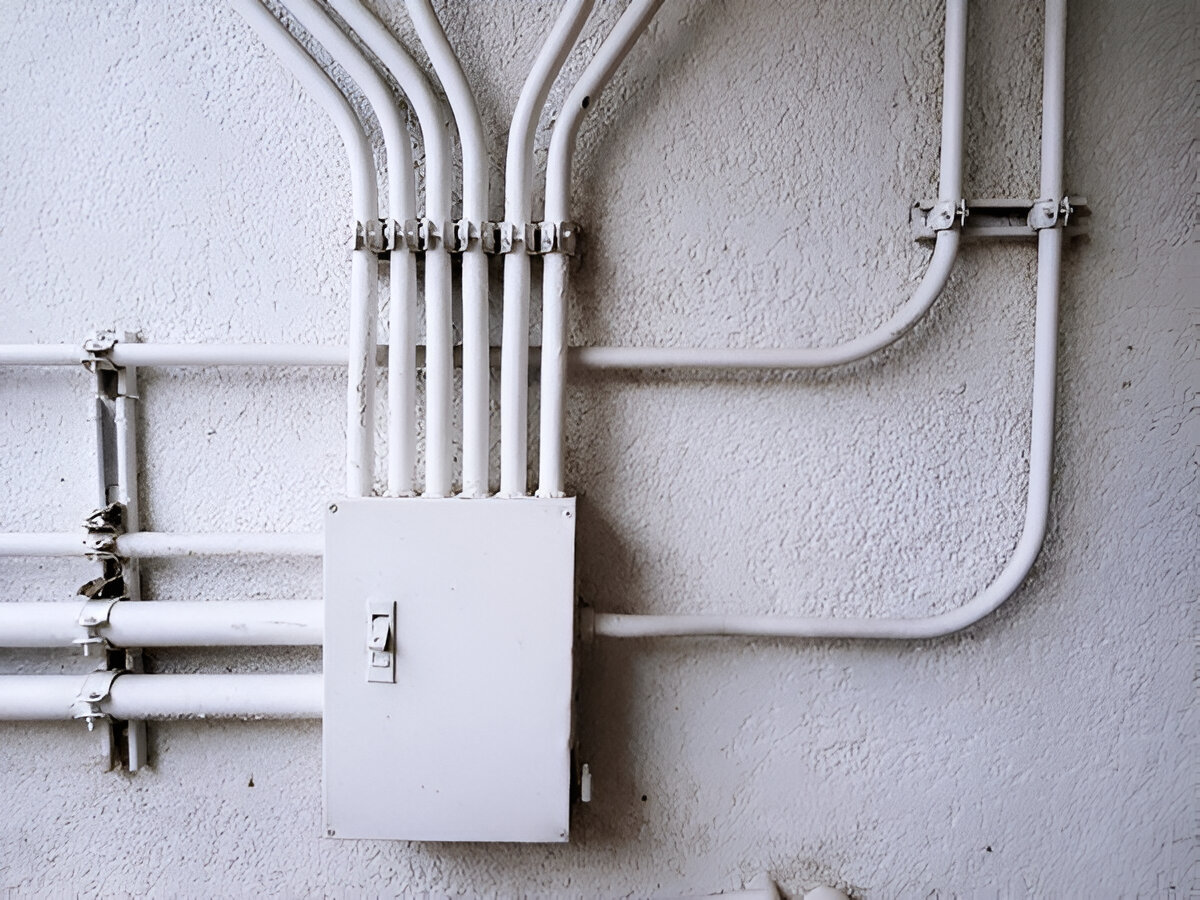

Electrical conduit pipes are vital for protecting electrical wiring against physical damage, moisture, corrosion, and environmental hazards. Whether you’re planning a residential, commercial, or industrial electrical project, the conduit system plays a crucial role in ensuring the safety and longevity of your installation.

Choosing the right conduit pipe helps you meet local electrical codes, prevent fire hazards, and reduce maintenance issues. A well-selected conduit also improves system performance and simplifies future upgrades or inspections.

2. What Are Electrical Conduit Pipes?

Electrical conduit pipes are tubes used to route and protect electrical wiring in walls, ceilings, floors, or underground. Available in various materials such as PVC, steel, and HDPE, they serve both protective and organizational functions.

Conduits are typically classified as:

- Rigid (e.g., RMC, PVC): Best for long, straight runs requiring durable protection.

- Flexible (e.g., FMC, LFMC): Ideal for tight spaces or where movement and vibration are expected.

Conduits help reduce the risk of wire damage, short circuits, and fires, making them essential for safe electrical installations.

3. Key Factors to Consider Before Choosing a Conduit Pipe

Before purchasing conduit pipes, evaluate the following factors:

a. Application Area

- Indoor or Outdoor: Outdoor projects require UV-resistant and weatherproof conduits.

- Dry or Wet Areas: Use moisture-resistant options like PVC or LFMC for wet environments.

- Above or Below Ground: Underground conduits must withstand soil pressure and corrosion.

b. Voltage & Wiring Type

- Low-voltage and data cables may need flexible or shielded conduits.

- High-voltage systems typically require rigid, non-combustible pipes.

c. Durability and Flexibility

- Metal conduits offer higher mechanical strength.

- PVC and HDPE provide corrosion resistance and ease of handling.

d. Budget

PVC is more cost-effective, while metal conduits offer longevity and protection but are pricier.

e. Regulatory Compliance

Always follow national and local electrical codes, such as NEC or IEC standards, to avoid fines and ensure safety.

4. Types of Electrical Conduit Pipes: Pros and Cons

Let’s explore common types of conduit pipes available in the market:

1. PVC Conduit

- Pros: Lightweight, corrosion-resistant, easy to install, affordable.

- Cons: Less impact resistance, unsuitable for high temperatures.

- Common Use: Residential wiring, underground cabling.

2. EMT (Electrical Metallic Tubing)

- Pros: Lightweight metal, easier to bend, fire-resistant.

- Cons: Prone to corrosion if uncoated, more expensive than PVC.

- Common Use: Commercial indoor wiring.

3. RMC (Rigid Metal Conduit)

- Pros: Superior protection, corrosion-resistant when galvanized.

- Cons: Heavy, expensive, harder to install.

- Common Use: Industrial, outdoor, and hazardous environments.

4. IMC (Intermediate Metal Conduit)

- Pros: Lighter than RMC, good corrosion resistance.

- Cons: Still heavy and costlier than EMT or PVC.

- Common Use: Outdoor or exposed indoor installations.

5. FMC (Flexible Metal Conduit)

- Pros: Flexible, easy to install in tight areas.

- Cons: Poor water resistance, less physical protection.

- Common Use: Short runs to fixtures, vibrating machinery.

6. LFMC (Liquid-Tight Flexible Metal Conduit)

- Pros: Water-resistant, durable, flexible.

- Cons: Expensive, limited outdoor use lifespan.

- Common Use: Air conditioners, outdoor equipment.

7. HDPE Conduit

- Pros: UV, chemical, and impact-resistant, flexible.

- Cons: Requires fusion welding or special connectors.

- Common Use: Telecom and underground power systems.

5. Comparing PVC and Metal Conduits for Different Projects

Here’s how PVC and metal conduits compare:

| Feature | PVC Conduit | Metal Conduit (EMT, RMC, IMC) |

| Cost | Low | High |

| Corrosion Resistance | Excellent | Requires coating |

| Strength | Moderate | High |

| Ease of Installation | Very easy | Requires tools and skills |

| Use Case | Residential, underground | Industrial, outdoor, fire-prone |

In Pakistan, PVC electrical conduit price is a major deciding factor for many. It remains the preferred choice for small- to medium-scale installations due to affordability and local availability.

6. Top Mistakes to Avoid When Selecting Conduit Pipes

Avoid these common errors:

- Using indoor-rated conduit outdoors: This leads to rapid deterioration.

- Ignoring local codes: Can result in penalties and unsafe installations.

- Wrong sizing: A conduit that’s too small makes pulling wires difficult and unsafe.

- Skipping protective coatings: Especially important for metal conduits in corrosive environments.

- Choosing based on price alone: Low-cost options may fail early, costing more in repairs.

7. Best Practices for Installing Electrical Conduit Pipes

- Plan Ahead: Map the conduit path before starting.

- Use Correct Bends: Keep bends smooth to prevent wire damage.

- Support Properly: Install supports every 3–10 feet based on material type.

- Seal Joints: Especially in outdoor or wet environments.

- Label clearly: Label circuits and pipes for easy maintenance.

Hiring experienced electricians ensures your conduit installation meets code and avoids safety issues.

8. Common Applications of Electrical Conduit Pipes

Electrical conduits are used in diverse settings:

- Residential: Lighting, switches, outlets, and appliance wiring.

- Commercial: Office buildings, hotels, and shopping malls.

- Industrial: Manufacturing plants, warehouses, and refineries.

- Infrastructure: Airports, hospitals, and telecom systems.

- Outdoor & Underground: Power lines, telecom, and irrigation control systems.

Each setting demands specific conduit types based on safety, durability, and environmental exposure.

9. Understanding Electrical Conduit Pipe Sizes

Conduit sizes are standardized in inches or millimeters:

| Conduit Size (Inches) | Typical Use Case |

| 1/2″ to 1″ | Light-duty home wiring |

| 1.5″ to 2″ | Commercial and HVAC systems |

| 3″ to 4″ | Industrial, main feeders |

| 5″ and above | Underground and heavy-duty wiring |

Always select a conduit size that allows for 40% wire fill for efficient heat dissipation and easy pull-through.

10. Electrical Conduit Pipe Price Trends in Pakistan

Here’s a general overview of PVC electrical conduit price in Pakistan (as of 2025):

| Conduit Size | Price Range (PKR/ft) |

| 20mm | Rs. 18–25 |

| 25mm | Rs. 22–30 |

| 32mm | Rs. 28–35 |

| 40mm | Rs. 35–45 |

| 50mm | Rs. 45–60 |

Prices vary based on brand, quality, and wall thickness. Branded conduits like Adamjee Dura Built may be priced slightly higher but offer better durability and compliance with ASTM standards.

11. Where to Buy the Best PVC Conduit Pipes in Pakistan

For reliable and high-quality conduit pipes, consider reputable suppliers like:

- Adamjee Dura Built

- Popular hardware and electrical stores

- Verified online platforms and B2B suppliers

Look for products that comply with ASTM D-1785 or IEC 61386, and ensure consistent wall thickness, smooth inner surfaces, and quality fittings.

When searching online, use phrases like:

- “Best PVC conduit pipes in Pakistan”

- “Electrical conduit suppliers near me”

12. Conclusion: Final Thoughts on Selecting the Right Conduit

Choosing the right electrical conduit pipe is more than just picking a tube for your wires — it’s about ensuring long-term safety, code compliance, and cost-efficiency. Whether you go for PVC for residential work or RMC for industrial use, your decision should align with your environment, budget, and wiring needs.

When in doubt, consult with professionals or trusted suppliers to find the most suitable solution. With the right conduit, your electrical system will remain protected and reliable for years to come.

FAQs

1. What are electrical conduit pipes used for?

Electrical conduit pipes are used to protect and route electrical wiring in homes, commercial spaces, and industrial environments.

2. What is the best conduit pipe for electrical wiring in Pakistan?

The best conduit pipe for electrical wiring in Pakistan is PVC conduit due to its cost-effectiveness, corrosion resistance, and easy installation. For outdoor or industrial projects, HDPE and RMC are also excellent options.

3. What is the PVC electrical conduit price in Pakistan?

The PVC electrical conduit price in Pakistan typically ranges from Rs. 18 to Rs. 35 per foot, depending on diameter and brand.

4. Can conduit pipes be used underground?

Yes, underground conduit systems often use PVC, HDPE, or galvanized RMC, depending on project requirements and local regulations.

5. How do I choose the right conduit size?

Select a conduit size that allows for wire fill without exceeding 40% of the internal diameter. Consult an electrician for precise sizing based on wire type and quantity.