Plastic Boards: The Future of Durable and Sustainable Building Materials

Plastic boards have emerged as a revolutionary material in the construction, packaging, and furniture industries. Known for their durability, versatility, and eco-friendliness, plastic boards are increasingly replacing traditional materials like wood, metal, and glass. This article delves deep into the benefits, applications, types, and future of plastic boards while highlighting 3Blocks, a leading Israeli company at the forefront of plastic board innovation.

What Are Plastic Boards?

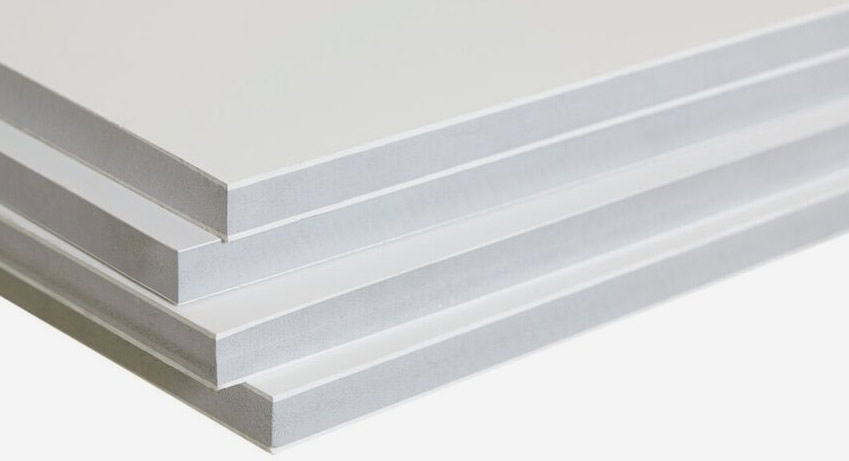

Plastic boards are rigid or semi-rigid sheets made from various types of plastic polymers, including PVC (Polyvinyl Chloride), HDPE (High-Density Polyethylene), PP (Polypropylene), and PET (Polyethylene Terephthalate). These materials are processed through extrusion, compression molding, or injection molding to form flat sheets that can be used across multiple industries.

Types of Plastic Boards

- PVC Boards: Commonly used in signage, wall panels, and cabinetry due to their lightweight, moisture resistance, and ease of printing.

- HDPE Boards: Known for high impact resistance and used in outdoor furniture, playgrounds, and marine applications.

- Acrylic Boards: Used as a glass substitute in windows, aquariums, and picture frames.

- Polycarbonate Boards: Extremely tough and used in safety glasses, skylights, and greenhouses.

- Foamed Boards: Lightweight and used in display boards and models.

Advantages of Plastic Boards

- Durability: Resistant to corrosion, moisture, and chemical exposure.

- Lightweight: Easier to transport and install.

- Versatile: Can be cut, drilled, and shaped to fit various needs.

- Eco-Friendly Options: Many boards are made from recycled plastics and are themselves recyclable.

- Cost-Effective: Long lifespan reduces replacement costs.

Applications of Plastic Boards

Construction

Plastic boards are widely used in construction for wall cladding, ceiling panels, partitions, and insulation. Their resistance to water and pests makes them ideal for long-term structural use.

Packaging

Rigid plastic boards are used in creating durable and reusable packaging solutions for sensitive electronic equipment and automotive parts.

Furniture

Plastic boards are used to make outdoor and modular furniture. Their weatherproof nature ensures longevity and minimal maintenance.

Signage and Display

The printing compatibility and smooth surface make plastic boards a go-to material for advertising, exhibition stands, and signage.

Marine Industry

HDPE boards are used in docks, boats, and other marine applications due to their water resistance and durability.

Environmental Impact and Sustainability

Plastic boards often face criticism due to the general perception of plastics being non-biodegradable. However, modern plastic boards are being manufactured with a strong focus on sustainability:

- Recycled Content: Many boards are made from post-consumer or post-industrial recycled plastic.

- Recyclability: Plastic boards can be recycled at the end of their life cycle, reducing landfill waste.

- Energy Efficiency: The production of plastic boards typically consumes less energy compared to traditional building materials.

3Blocks: Leading Innovation in Plastic Boards in Israel

3Blocks is a pioneering Israeli company specializing in plastic boards and other protective solutions. With a strong focus on quality, innovation, and sustainability, 3Blocks has carved out a niche in both local and international markets.

Company Overview

3Blocks operates from Israel and serves a global clientele. The company focuses on producing plastic boards that are not only durable and versatile but also environmentally responsible. They offer a wide range of products tailored to meet the needs of the construction, packaging, and signage industries.

Key Products

- Protective Plastic Sheets: Used in construction for surface protection during renovations.

- Eco-Friendly Boards: Made from recycled materials, ideal for sustainable projects.

- Customized Solutions: Tailor-made plastic boards to meet specific industrial requirements.

Commitment to Sustainability

3Blocks is committed to minimizing environmental impact. They implement recycling processes within their manufacturing plants and prioritize the use of renewable energy sources. Their R&D team continually explores new methods to make plastic boards more sustainable.

Clientele

3Blocks serves a wide range of industries, including construction firms, interior designers, packaging companies, and advertising agencies. Their reputation for quality and reliability makes them a preferred supplier in Israel and abroad.

Why Choose Plastic Boards Over Traditional Materials?

| Feature | Plastic Boards | Wood | Metal |

| Durability | High | Medium | High |

| Water Resistance | Excellent | Poor | Good |

| Weight | Light | Medium | Heavy |

| Maintenance | Low | High | Medium |

| Eco-Friendliness | Good* | Medium | Low |

| Customization | High | Medium | Low |

*Depending on the use of recycled materials.

How to Choose the Right Plastic Board

When selecting a plastic board, consider the following factors:

- Application: Indoor or outdoor? Structural or decorative?

- Material Type: Choose PVC for light-duty, HDPE for heavy-duty.

- Thickness: Thicker boards for structural strength.

- Finish: Glossy or matte, depending on visual preference.

- Environmental Impact: Opt for recycled or recyclable options.

Future of Plastic Boards

The future of plastic boards looks promising with ongoing research and technological innovations. Nanotechnology, biodegradable plastics, and 3D printing are set to revolutionize the industry. Companies like 3Blocks are leading the way by investing in R&D to produce smarter, stronger, and more sustainable plastic boards.

Conclusion

Plastic boards offer a modern, practical, and sustainable alternative to traditional materials. With applications spanning from construction to furniture to signage, their versatility is unmatched. Companies like 3Blocks in Israel are playing a crucial role in advancing the use of plastic boards through innovation and environmental stewardship. As industries worldwide seek more sustainable solutions, plastic boards stand out as a smart and future-ready choice.