Why Thermal Property Testing Matters for 2025 Engineering

In today’s fast moving world of engineering it is paramount to follow the latest developments. One area that has gained traction and is worthy of notice is thermal property testing. This type of testing will be essential to the improvement of many engineering processes in 2025, following and possibly even revolutionizing other developments in engineering, especially in manufacturing, aerospace, automotive, and material sciences.

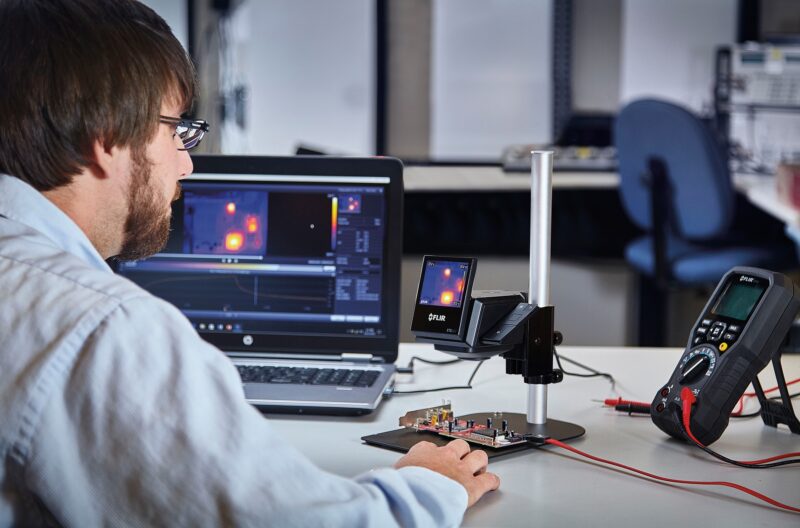

Understanding Thermal Property Testing

Thermal Property Testing involves measuring a material’s response to changes in temperature. This process helps engineers assess how materials will behave under various thermal conditions. Testing can cover several properties, such as thermal conductivity, thermal expansion, and specific heat capacity. Among the most important tests are thermal diffusivity testing services and thermal analysis services, which are used to determine how well a material conducts heat and how it expands or contracts when heated.

These tests are essential in determining whether a material is suitable for a specific application, especially in high-performance industries where materials face extreme temperatures.

The Rise of Metal 3D Printing in Engineering

Metal 3D printing is revolutionizing manufacturing by enabling the creation of complex, custom-designed parts that are lighter, stronger, and more efficient than traditional methods. As companies move towards Metal 3D Printing Service, the demand for precise thermal property data has never been higher.

Understanding the thermal properties of the materials being used in metal 3D printing is crucial for ensuring the stability and performance of the printed parts. The heat involved in 3D printing processes can cause warping, cracking, or structural failure if the material is not chosen correctly. Therefore, engineers must rely on thermal diffusivity testing to gauge how different materials will behave under the intense heat of the printing process.

Key Thermal Properties in Engineering

Several thermal properties are tested to ensure that materials will perform reliably in a wide range of engineering applications:

- Thermal Conductivity: This property determines how well a material can transfer heat. Materials with high thermal conductivity, like metals, are often used in applications where heat needs to be dissipated quickly, such as in heat exchangers. Conversely, materials with low thermal conductivity are used in insulation applications.

- Thermal Expansion: As materials heat up, they expand. This property is crucial in applications where materials are exposed to temperature changes, such as in aerospace or automotive parts. Testing thermal expansion ensures that parts will fit together correctly, even in extreme conditions.

- Specific Heat Capacity: This refers to the amount of heat required to raise the temperature of a material by one degree. Materials with high specific heat are used where heat storage is needed, such as in batteries or thermal storage systems.

Why Thermal Property Testing is Essential in 2025

As industries continue to push the boundaries of technology, thermal property testing becomes increasingly vital in ensuring the success of various engineering projects. Here are some key reasons why thermal property testing matters for engineering in 2025:

Better Material Selection

Choosing the right material for a project is critical. Thermal testing provides engineers with the data they need to pick materials that can handle specific temperature conditions. For example, in aerospace, materials that resist high heat and maintain strength are essential. In these cases, thermal testing ensures engineers make the best choice.

Improved Product Performance

Many products, such as engines, turbines, and electronics, operate under high heat. Without proper testing, these products may fail. Thermal analysis service help engineers fine-tune their designs and ensure the parts perform reliably, even in extreme conditions. At ACS Material, we understand the importance of testing for performance and reliability.

Better Manufacturing Processes

Thermal testing also improves manufacturing processes, such as metal 3D printing. In 3D printing, heat can cause defects. If a material expands or warps too much during printing, the part could be ruined. By understanding thermal properties, engineers can adjust the printing parameters to avoid these issues.

Driving Innovation

Thermal property testing enables engineers to push the boundaries of what’s possible. With the rise of thermal analysis , engineers can create new materials for energy storage, better heat exchangers, and more efficient systems. Thermal testing helps them innovate and design products that are both more efficient and more durable.

Promoting Sustainability

In today’s world, energy efficiency is crucial. Thermal property testing helps engineers design products that save energy. For example, materials that efficiently store or dissipate heat are used in energy-efficient buildings or power plants. Thermal testing is key to ensuring that products meet sustainability goals.

Conclusion

In 2025, testing thermal properties will be pivotal for engineering disciplines. Industries like metal 3D printing services, aerospace, and electronics are evolving rapidly, highlighting the need for engineers to understand heat reactions of materials and informed decisions in product and testing cycles. Engineers can utilize thermal analysis services across common engineering, including products that incorporate thermal testing services, to improve performance, improved safety, or discover new possibilities.